Product Categories

Structural Steel

Starting from 2008, Zamil Steel extended its structural steel fabrication division to Vietnam for targeting the highly potential industrial prosperity in Vietnam and the Asia Pacific region.

A state-of-the-art manufacturing facility was established in Dong Nai, Vietnam, specializing in structural steel fabrication. The facility utilizes the latest Engineering software for Structural Steel Analysis, Connection Design & Shop Drawings Preparation and state-of-the-art Computer Numerical Coded (CNC) equipment for controlling fabrication process.

With an excellent track record in structural steel fabrication for nearly 40 years, we bring you a total steel buildings solution that exceeds your expectation in terms of quality and functionality. Our values are best described with:

A proven track record & experience

- Manufactured and supplied over 60,000 steel buildings worldwide.

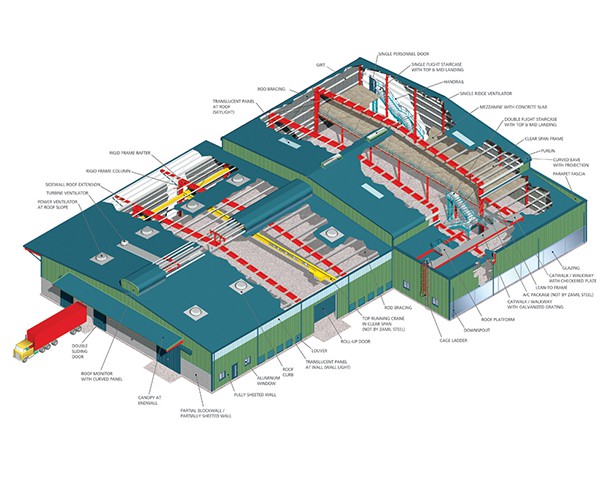

- Building applications range from High-rise Buildings, Warehouse, Oil & Gas Plant, Petrochemical Plants, and Industrial Buildings to Power & Desalination Plants.

- Largest project recorded: 15, 000 metric tons.

Strong Technical & Engineering Expertise

- 100% CAD and full design automation

- Cutting-edge in-house design software for detailing

- Reliable design software (STAA PRO, SAP 2000, TEKLA, RAM Connection, LIM connection & Detailing) for structural analysis design

- Utilizing the most Updated CAD software systems (such as AutoCAD and Micro Station) to provide accurate and high quality engineering drawings.

State-of-the-art Manufacturing Facilities

- Computer Numerical Coded (CNC) Drill Lines, completed with drills and band saws for raw materials and plates drillings

- CNC flame cutting equipment

- Fully Automatic Submerged Arc Welding (SAW) Lines.

- Stud welding machines

- In house 16-wheel shot blasting machinery.

- 75 Overhead and Jib Cranes.

- Comprehensive container loading facilities.

Optimized fabrication time and delivery schedule

- Comprehensive in-house scheduling system to generate global fabrication and master plan;

- Coordinated tracking system (Oracle ERP) to monitor turnaround time from Purchase of raw materials to Shipment of buildings.

Systematic Quality Assurance and Control

- Stringent Internal Quality Control system ensuring all products are manufactured to strict international standards and specification.

- Quality Control Engineers are certified to American Society of Nondestructive Testing (ASNT) Level III, Level II, America Welding Society (AWS) and BGAS-CSWIP.

- ISO:9001:2000 certified manufacturing processes

International Recognition of QUALITY

- ISO 9001:2000 Certification by BVQI

- Accredited Structural Steel Fabricator of Singapore Structural Steel Society – S1

- Certificate of Compliance from Japan Ministry of Land, Infrastructure and Transport (MLIT)

- IBS Status manufacturer verified by CIDB Malaysia

Excellent Service

- 100% commitment during project life-cycle

- Erection coordinator exclusively assigned to monitor and manage the entire erection process, ensuring the building is erected to the best industrial practices and specifications.

- Archive of project documents library for future reference and usage.