1995: Establishment of Lotus Chemical Technology Ltd. in Ho Chi Minh City

1996: A factory producing plastic films for the export market is built in Ho Chi Minh City

1997: Expansion to Northern Vietnam by building a factory for the production of PVC compound in Hai Phong City

2003: The Hai Phong branch becomes an independent company, Lotus Hai Phong Ltd., and builds a new factory of 30.000 m2 for the production of PVC compound and plastics construction materials.

2004: In joining RKW AG - Europe’s leading manufacturer of polyethylene and polypropylene films, nonwovens and nets - RKW Lotus Ltd. is established, specializing in the production of polyethylene film and - carrier bags for consumer and industrial Packaging.

2012: Building Cat Lai warehouse

Coming Project: Building RKW Lotus Asia at Sai gon High tech park

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Link with

Province/City

Ho Chi Minh City

Industrial Park

Cat Lai II Industrial Park

Location Map & Landmarks

On-sale Properties

Products of the company

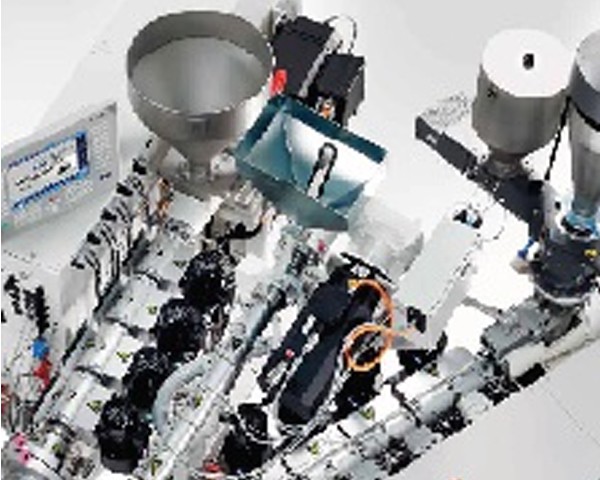

36D twin-screw extruders for economical PVC pipe extrusion

36D long procedural concept for high-performance and flexible production

The parallel twin-screw extruders of the 36D series from KraussMaffei Berstorff are specially designed for PVC processing. A broad product line with modular concept offers economical and high-performance production solutions – adapted to the needs of the customer. A perfectly optimized screw concept provides for very gentle and uniform material processing. Long process units increase the process reliability and offer high production reliability in a broad range of applications. With their HPG screw concept (High Performance Geometry), the models of this series are optimally suited for producing a wide variety of PVC formulations, such as U-PVC, M-PVC, foamed PVC or PVC-O mixes. Additionally, cost-effective materials with high filler content can be processed ideally.

They feature outstanding properties, such as high outputs, excellent melt quality, optimum melt temperature, and an extremely low maintenance effort.

Our product portfolio extends from model KMD 75-36 E/R to KMD 133-36 E/R

High quality and output during production of PO large pipes with the 36D single-screw technology from KraussMaffei Berstorff

During large pipe extrusion, along with the need for high output, the reduction of weight per meter and, with it, the material costs are of great importance. With the KraussMaffei Berstorff 36D series single-screw extruder, the challenges connected with the success criteria for pipe extrusion process technology can likewise be solved cost-effectively and reliably. Moreover, it guarantees optimum melt homogeneity at the lowest melt temperature.

Additional advantages are plain to see:

Increase in process reliability and minimized screw and barrel wear

Optimum pipe quality at high production reliability

Pipes with minimum internal stress and ovality

Broad processing windowHigh production flexibility

In connection with the spiral distributor pipe head, a seamless production of PO pipes up to a diameter of 2,500 mm with pipe wall thickness of up to 100 mm is guaranteed.

These types of pipes are used particularly in drinking and drainage water transport, across large distances and for large-scale consumers. Other fields of application are salt water desalination plants and cooling water lines for power plants.

KraussMaffei Berstorff provides complete systems from a single source as a system solution.

As a system provider, KraussMaffei Berstorff offers all components for manufacturing plastic pipes with a diameter from 5 to 2500 mm, including automation components. Our product line covers single-screw extruders, counter-rotating and co-rotating twin-screw extruders with the corresponding pipe heads, downstream components and peripheral devices, and fully automatic pipelines. All our components and automation systems are consistently designed for the highest degree of material, energy and cost savings with a uniformly high quality of products. For every application, we offer systems tailored to the customer's wishes from a single source.

Double and single-screw extruders are the core of a complete system. Modular construction, with integrated control cabinet and control panel, makes it possible to be used for any customer-specific application. All downstream components such as the vacuum tank, the spray tank, the haul-off, cutting units, socket forming machines and additional equipment are optimally tuned to one another; the automation components are designed for maximum operational safety and ease of operation and servicing. With the complete system, optional pipe winders, supplemental systems such as filling units or extended automation equipment such as bundling or palletizing machines can also be provided. The KraussMaffei Berstorff C5 control system, as one of the most modern control, regulation and monitoring systems in extrusion, has intelligent functions for a central line control system.

41D single-screw extruder for high-performance extrusion

High-performance extrusion with the single-screw extruder series of the 41 L/D processing unit

The series with the 41 L/D processing unit is ideally suited to high-performance requirements when processing PE and PP.

Combined with the patented screw concept, the real 41 L/D processing length – as a continuous new development from the proven and successful 36D single-screw series – offers a disproportionate increase in specific throughput and, at the same time, enables low melt temperatures, which bring about outstanding homogeneity.

The latest drive technology with AC motors and efficient gearbox ensures energy-saving production.

Your benefits at a glance

Constant output rates with a consistently excellent product quality

Remarkably high throughput with perfect finished product quality

Low-maintenance drive technology with energy-efficient AC motors

A patented screw concept guarantees that the plasticizing unit is extremely gentle on material

Bimetal barrels and optional through-hardened grooved bushes ensure perfect wear-resistance