VRG Dongwha MDF was established in 2008 by a joint venture between Dongwha International, a world-leading Korean company in wood panel industry and Vietnam Rubber Group, a state-own conglomerate well-known for its leading role in Vietnam rubber plantation and processing industry which is located in Binh Phuoc, Vietnam in a 39 hectares area. This MDF manufacturing plant is located in Minh Hung Commune which is close to Vietnam’s economic capital Ho Chi Minh City. Raw materials will be mainly Rubber Wood, Acacia Melalecusa, Cashew and Pine supplied by Binh Phuoc, Binh Duong, Tay Ninh and Dak Nong provinces. VRG Dongwha MDF will be exported as well as meet rising demands for this product on the Vietnam domestic market. This will significantly promote Vietnam’s modernization and industrialization process in wooden industry.

VRG Dongwha MDF has invested US$ 160 million fiberboard project since July 13, 2010. It is the largest and most modern MDF/HDF plant in Asia, equipped with advanced environmental-friendly technology and modern facilities from Germany, Sweden and Finland. Most of the machineries are designed by Siempelkamp, to bring out finest MDF products with total annual capacity of 300,000 ㎥. The plant is equipped with an 8’ x 47m ContiRoll® press which will make it the largest MDF plant in Asia. Siempelkamp also be responsible for the engineering of the plant and a large portion of the front-end equipment. The scope of supply includes a drum chipper, chip storage, screens, conveyors, silos as well as a fiber dryer and a fiber sifter which is custom-designed for fibrer produced from rubber tree. The complete glue blending system is also supplied by Siempelkamp.

Under the management and supervision of Dongwha experienced foreign and local experts, our products can meet any qualifications demanded in wood panel products. Optimizing customer’s satisfaction is our top priority. Thus, producing products with best quality and best services is defined as our top mission to meet our customer needs.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Link with

Province/City

Binh Phuoc Province

Industrial Park

Minh Hung III Industrial Park

Location Map & Landmarks

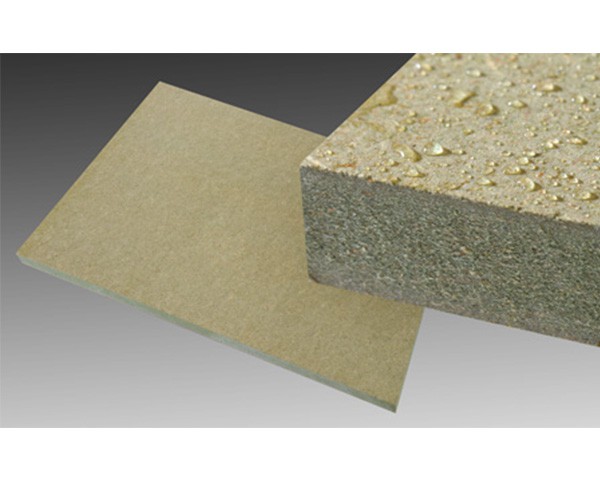

Products of the company

| Board Properties | Test Method | Unit | ≥ 9.0 - 12.0 | ≥ 12.0 - 19.0 |

|---|---|---|---|---|

| Thickness tolerance | BS EN 324-1 | mm | ±0.2 | |

| Size tolerance (length & width) | BS EN 324-1 | mm | ±5 mm | |

| Squareness (diagonal) | BS EN 324-2 | mm | < 5.0 | |

| Average density | BS EN 323 | kg/㎥ | 620 | 600 |

| Board moisture | BS EN 322 | % | 5.0 - 8.0 | |

| Internal Bond(IB-dry) Average | BS EN 319 | N/㎟ | 0.45 | 0.45 |

| Modulus of rupture (MOR) | BS EN 310 | N/㎟ | 18 | 18 |

| Modulus of Elasticity (MOE) | BS EN 310 | N/㎟ | 1800 | 1800 |

| Thickness swelling (24hr) | BS EN 317 | % Max |

20 | 18 |

| Properties | Test Method | Unit | Standard |

|---|---|---|---|

| Small Chamber | D6007-02 | ppm | Phase2 Thin board (<=8mm) : < 0.13 Thick board (>8mm) : < 0.11 |

| Formaldehyde Emission (Perforator) |

BS EN 120 | mg/100g (Average) | E0 ≤ 3.0 3.0 < E1 ≤ 9.0 9.0 < E2 ≤ 30 |

| Formaldehyde Emission (Desiccators) |

JIS A 1460 | mg/l (Average) | F* ≤ 2.1 F** ≤ 1.5 F*** ≤ 0.5 F**** ≤ 0.3 |

| Board Properties |

Test Method |

Unit | ≥ 2.5 - 4.0 |

≥ 4.0 - 6.0 |

≥ 6.0 - 9.0 |

≥ 9.0 - 12.0 |

≥ 12.0 - 19.0 |

≥ 19.0 - 30 |

|---|---|---|---|---|---|---|---|---|

| Thickness tolerance | BS EN 324-1 |

mm | ±0.15 | ±0.15 | ±0.2 | ±0.2 | ±0.2 | ±0.2 |

| Size tolerance (length & width) |

BS EN 324-1 |

mm | ±5mm for free trim panel ±2mm for net size panel |

|||||

| Squareness (diagonal) |

BS EN 324-2 |

mm | <5.0 | |||||

| Average density | BS EN 323 |

kg/㎥ | 800 | 780 | 740 | 720 | 700 | 680 |

| Board moisture | BS EN 322 |

% | 5.0 - 8.0 | |||||

| Internal Bond(IB) Average |

BS EN 319 |

N/㎟ | 0.70 | 0.70 | 0.80 | 0.80 | 0.75 | 0.75 |

| Modulus of rupture (MOR) |

BS EN 310 |

N/㎟ | 27 | 27 | 27 | 26 | 24 | 22 |

| Modulus of Elasticity (MOE) |

BS EN 310 |

N/㎟ | 2700 | 2700 | 2700 | 2500 | 2400 | 2300 |

| Screw holding Surface |

BS EN 320 |

N | NA | NA | NA | NA | 1050 | 1000 |

| Screw holding Edge | BS EN 320 |

N | NA | NA | NA | NA | 850 | 850 |

| Thickness swelling (24hr) |

BS EN 317 |

% Max |

30 | 18 | 12 | 10 | 8 | 7 |

| MOR under wet condition |

JIS 5905 | N/㎟ | 15 | 12.5 | 7.5 | |||

| Properties | Test Method | Unit | Standard |

|---|---|---|---|

| Small Chamber | D6007-02 | ppm | Phase2 Thin board (<=8mm) : < 0.13 Thick board (>8mm) : < 0.11 |

| Formaldehyde Emission (Perforator) |

BS EN 120 | mg/100g (Average) | E0 ≤ 3.0 3.0 < E1 ≤ 9.0 9.0 < E2 ≤ 30 |

| Formaldehyde Emission (Desiccators) |

JIS A 1460 | mg/l (Average) | F* ≤ 2.1 F** ≤ 1.5 F*** ≤ 0.5 F**** ≤ 0.3 |

| Properties | Test Method | Unit | Standard |

|---|---|---|---|

| Small Chamber | D6007-02 | ppm | Phase2 Thin board (<=8mm) : < 0.13 Thick board (>8mm) : < 0.11 |

| Formaldehyde Emission (Perforator) |

BS EN 120 | mg/100g (Average) | E0 ≤ 3.0 3.0 < E1 ≤ 9.0 9.0 < E2 ≤ 30 |

| Formaldehyde Emission (Desiccators) |

JIS A 1460 | mg/l (Average) | F* ≤ 2.1 F** ≤ 1.5 F*** ≤ 0.5 F**** ≤ 0.3 |

| Board Properties |

Test Method |

Unit | ≥ 2.5 - 4.0 |

≥ 4.0 - 6.0 |

≥ 6.0 - 9.0 |

≥ 9.0 - 12.0 |

≥ 12.0 - 19.0 |

≥ 19.0 - 30.0 |

|---|---|---|---|---|---|---|---|---|

| Thickness tolerance | BS EN 324-1 |

mm | ±0.15 | ±0.15 | ±0.2 | ±0.2 | ±0.2 | ±0.2 |

| Size tolerance (length & width) |

BS EN 324-1 |

mm | ±5mm for free trim panel ±2mm for net size panel |

|||||

| Squareness (diagonal) |

BS EN 324-2 |

mm | <5.0 | |||||

| Average density | BS EN 323 |

kg/㎥ | 800 | 780 | 740 | 720 | 700 | 680 |

| Board moisture | BS EN 322 |

% | 5.0 - 8.0 | |||||

| Internal Bond(IB-dry) Average |

BS EN 319 |

N/㎟ | 0.65 | 0.65 | 0.65 | 0.60 | 0.55 | 0.55 |

| Modulus of rupture (MOR) |

BS EN 310 |

N/㎟ | 23 | 23 | 23 | 22 | 20 | 18 |

| Modulus of Elasticity (MOE) |

BS EN 310 |

N/㎟ | NA | 2700 | 2700 | 2500 | 2200 | 2100 |

| Screw holding Surface |

BS EN 320 |

N | NA | NA | NA | NA | 1050 | 1000 |

| Screw holding Edge | BS EN 320 |

N | NA | NA | NA | NA | 850 | 850 |

| Thickness swelling (24hr) |

BS EN 317 |

% Max |

≤35 | ≤30 | ≤17 | ≤15 | ≤12 | ≤10 |

| Surface absorbtion (Toluence test) |

In-House | mm (min) |

Premium Grade:≥120 Utility Grade:≥80 |

Premium Grade:≥150 Utility Grade:≥80 |

||||

| Properties | Test Method | Unit | Standard |

|---|---|---|---|

| Small Chamber | D6007-02 | ppm | Phase2 Thin board (<=8mm) : < 0.13 Thick board (>8mm) : < 0.11 |

| Formaldehyde Emission (Perforator) |

BS EN 120 | mg/100g (Average) | E0 ≤ 3.0 3.0 < E1 ≤ 9.0 9.0 < E2 ≤ 30 |

| Formaldehyde Emission (Desiccators) |

JIS A 1460 | mg/l (Average) | F* ≤ 2.1 F** ≤ 1.5 F*** ≤ 0.5 F**** ≤ 0.3 |