Zamil Steel Buildings Vietnam Co., Ltd is a joint venture between Zamil Industrial Investment Company and Mitsui & Co., Ltd.

Zamil Steel group of companies, a subsidiary of Zamil Industrial Investment Company, was established in 1977. Zamil Steel is a global leader in the manufacture of pre-engineered steel buildings and the Middle East’s premier supplier of structural steel products and process equipment, transmission and telecommunications towers, open web steel joists, and roof& floor steel decks.

In 1993, the company set up a representative office in Ho Chi Minh City, Vietnam and began exporting steel buildings to the South East Asia region.

Four years later, in 1997, witnessing the robust growth potential of South East Asia, Zamil Steel took early initiatives to build our first plant in the Noi Bai Industrial Zone, Hanoi. The co-investment between Zamil Steel and Mitsui & Co., Ltd has resulted in a 100% foreign owned joint-venture – Zamil Steel Buildings Vietnam Co., Ltd.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Link with

Province/City

Dong Nai Province

Industrial Park

An Ha Industrial Park

Location Map & Landmarks

On-sale Properties

NAICS/SIC/VN Code

331513

331512

331511

331221

331210

331110

3399

3325

3324

3322

3321

3317

3316

3313

3312

24100

Products of the company

Zamil Steel Buildings Vietnam Co., Ltd also launched our Component Sales to the market with the purpose to help customers to have more options of accessories for their new steel buildings and replacement of the old ones.

The components are designed and fabricated in accordance with Zamil Steel standards, with high quality, good appearance, durability, and diversification.

The list of available components are mentioned below for your reference.

Contact any of our sales offices for technical advice and to order at your convenience.

List of our available components:

- Tempcon Panel with standard color

- MaxSEAM panel for new roof and re-roofing

- Panel type “S” 0.5mm thick with five standard colors

- Curved Panel with profile type “S”

- Ridge Ventilator package and all accessories

- Sliding Door and accessories

- Roll-up Door

- Personnel Doors: Single, Double, and Pilot

- Aluminum Window

- Steel Louver

- Steel Gutter, Downspout and its accessories

- Decking Panel type “K”

- Cold-form Section: Purlin, Girt, Base and Gable Angle

- Connection Bolt, Nut, Washer and Galvanized Anchor Bolt

- Galvanized Sag Rod

- Fasteners/Pop Rivet for roof and wall

- Bracing Components: Rod, Hillside and Coupling Washer

- Angles/Clips/Plates: for universal purposes

- Foam closure for type “S” panel

- Foam Gasket for modified panel profile

- PVC Pipe and Accessories

- Stainless Steel Roof Curb for roof

- Sealant for roof and wall panels: Flowable Mastic, Bead Mastic

- Insulation and Accessories

- Paint/Touch-up paint for main frames and panels

- Trims as per Standard and Customer’s Profile

- Identical building/identified member of built-up

- Power Ventilator

- Bird Screen/Insect Screen; Stainless Steel Wire Mesh

- Pipe Flashing

The application of Standing Seam Roof systems (SSRs) have been one of the most exciting breakthroughs in roofing technology in the last 30 years. For the past few years, they have been widely used in almost 50% of all low-rise commercial, industrial and institutional buildings across United States, Europe and other regions. SSRs have also proven to be the most efficient, effective and value-for-money roofing systems for construction in rainy, windy and tropical regions.

The Zamil Steel MaxSEAM roof system is one of the strongest and most weather-tight standing seam roof systems available in the industry today

The product features a 360-degree seam along the side laps of the panel; a special type of sliding clip; and a carefully engineered system for improving strength, durability and resistance to weather.

The MaxSEAM roof system acts as a monolithic membrane that completely protects your building, and is the most recommended roof system for tropical, rainy, snowy or high wind (cyclonic) regions.

Using Zamil Steel’s Super SEAMER machine, the side laps of adjacent panels are seamed together, creating a 360 degree. double-lock seam, which has machine-applied mastic to ensure a secure, weather tight leak-proof joint. To increase weather-tightness level of this roofing system, the end laps could be eliminated by rolling MaxSEAM panels on site, using a mobile roll former.

With our mobile roll former, the standard MaxSEAM panels (rolled formed in-house) have a maximum length of 11.5meters, while it can achieve a length up to 100 meters* when rolled on site.

Benefits

Weather-tightness

MaxSEAM assures adequate drainage from rain and snow.

Designed as a water barrier, the raised seam assists drainage; while the end laps, inside closure, outside closure, tri-bead mastic, along with the machine-applied sealant (inside the seams), increases the lap tightness further.

Thermal Movement & Leakage Prevention

The fastening system of MaxSEAM is designed to handle the potentially damaging effects of thermal movement (especially heat expansion).

The system features a sliding clip which slides between the base components and intermediate components to eliminate binding and offers greater flexibility for durability and thermal movement, while also minimizing the probability of leakage.

Unlike most other SSR systems, the gables at both ends of the roof finish with a 76 mm high standing seam, instead of finishing in the low, flat part of the panel, where the greatest possibilities for leaks occurs.

Cost Effectiveness

The life cycle cost of the MaxSEAM roof system is lower than any other steel panel roof system. Using Zincalume coated steel, its life expectancy is longer since less maintenance is required.

Quality Tests

Uplift ratings

Carries UL90 Uplift ratings and covers a wide range of installation procedures, MaxSEAM has met all test requirements as specified in CEGS 07416 Standing Seam Metal Roofing System Guide Spec.

FM Global Approved

Tested under ASTM E1646 “Standard Test Method for Water Penetration through Exterior Metal Roof Panel System” and ASTM E1680” Test Method for Rate of Air Leakage through Exterior Metal Roof Panel System”, MAXSEAM has achieved FM Global’s Approval as a Class 1 Roof Panel.

Under the same certification, MaxSEAM also meets Class 1-SH hail damage requirements and ‘Class 1A Fire Classification when installed at a maximum roof slope of 5 in 12 (42%).

High-Quality Materials

MaxSEAM panels are available in 0.5 mm- 18” panel width Zincalume coated steel.

The Panels conform to ASTM A729M Grade 345B and are coated with a protective layer of Zincalume (55% aluminum, 1.6% silicon and 43.4% Zinc) alloy coating (150g/m2 on both sides).

The steel panels are available in 0.53mm (nominal) bare Zincalume or 0.56mm (nominal)- 24” panel width, exterior roofing and walling (XRW) pre-painted Zincalume. Please refer to Zamil Steel sales representatives for availability of non-standard colors and non-standard coating systems (Exterior Premium Durability- XPD or Polyvinyl Fluoride- PVF2). We can provide you different options for:

- Sketch of panels

- Physical properties

- Load Tables

- Material Specifications

Convenient Installation

MaxSEAM roof system is installed using MaxSEAM Mobile Roll Former and SuperSEAMER machine.

Using the Zamil Steel SuperSEAMER, the side laps of adjacent panels are seamed together through a mechanical action, creating a 360 deg. double lock seam, which has a machine applied mastic to ensure a secure and weather tight leak proof roofing system.

After pre-seaming the start of the panels using a Seaming hand tool, the SuperSEAMER is then fitted on to the pre-seamed panel, adjusted and locked, before the rollers are activated to start the complete electric seaming process. With the simple and quick release handle, it only requires a very short time to move the SuperSEAMER from one seam to another. Weather-tight 360 deg. seams are made without affecting the panel paint finish.

The MaxSEAM mobile roll former will be used in case end laps are not preferred in the roofing system. The roll former machine weighs approximately 3.5 MT and can be transported to most jobsite via a container. With a roll forming capacity of between 12-15m per minute, MaxSEAM panels can be roll formed on site as a continuous panels for up to 100m. Depending on the project size and requirements, Zamil Steel will consult with you for onsite-roll-forming of panels with length exceeding 50 meters.

Zamil Steel has appointed Authorized Installers of MaxSEAM (AIMs) are assigned by Zamil Steel among our Certified Builders, who are adequately trained and experienced and possess the necessary facilities for installing MaxSEAM. Zamil Steel strongly recommends that all MaxSEAM roof systems should be installed only by one of our AIMs.

Contact Zamil Steel for the latest list of AIMs in your region.

Starting from 2008, Zamil Steel extended its structural steel fabrication division to Vietnam for targeting the highly potential industrial prosperity in Vietnam and the Asia Pacific region.

A state-of-the-art manufacturing facility was established in Dong Nai, Vietnam, specializing in structural steel fabrication. The facility utilizes the latest Engineering software for Structural Steel Analysis, Connection Design & Shop Drawings Preparation and state-of-the-art Computer Numerical Coded (CNC) equipment for controlling fabrication process.

With an excellent track record in structural steel fabrication for nearly 40 years, we bring you a total steel buildings solution that exceeds your expectation in terms of quality and functionality. Our values are best described with:

A proven track record & experience

- Manufactured and supplied over 60,000 steel buildings worldwide.

- Building applications range from High-rise Buildings, Warehouse, Oil & Gas Plant, Petrochemical Plants, and Industrial Buildings to Power & Desalination Plants.

- Largest project recorded: 15, 000 metric tons.

Strong Technical & Engineering Expertise

- 100% CAD and full design automation

- Cutting-edge in-house design software for detailing

- Reliable design software (STAA PRO, SAP 2000, TEKLA, RAM Connection, LIM connection & Detailing) for structural analysis design

- Utilizing the most Updated CAD software systems (such as AutoCAD and Micro Station) to provide accurate and high quality engineering drawings.

State-of-the-art Manufacturing Facilities

- Computer Numerical Coded (CNC) Drill Lines, completed with drills and band saws for raw materials and plates drillings

- CNC flame cutting equipment

- Fully Automatic Submerged Arc Welding (SAW) Lines.

- Stud welding machines

- In house 16-wheel shot blasting machinery.

- 75 Overhead and Jib Cranes.

- Comprehensive container loading facilities.

Optimized fabrication time and delivery schedule

- Comprehensive in-house scheduling system to generate global fabrication and master plan;

- Coordinated tracking system (Oracle ERP) to monitor turnaround time from Purchase of raw materials to Shipment of buildings.

Systematic Quality Assurance and Control

- Stringent Internal Quality Control system ensuring all products are manufactured to strict international standards and specification.

- Quality Control Engineers are certified to American Society of Nondestructive Testing (ASNT) Level III, Level II, America Welding Society (AWS) and BGAS-CSWIP.

- ISO:9001:2000 certified manufacturing processes

International Recognition of QUALITY

- ISO 9001:2000 Certification by BVQI

- Accredited Structural Steel Fabricator of Singapore Structural Steel Society – S1

- Certificate of Compliance from Japan Ministry of Land, Infrastructure and Transport (MLIT)

- IBS Status manufacturer verified by CIDB Malaysia

Excellent Service

- 100% commitment during project life-cycle

- Erection coordinator exclusively assigned to monitor and manage the entire erection process, ensuring the building is erected to the best industrial practices and specifications.

- Archive of project documents library for future reference and usage.

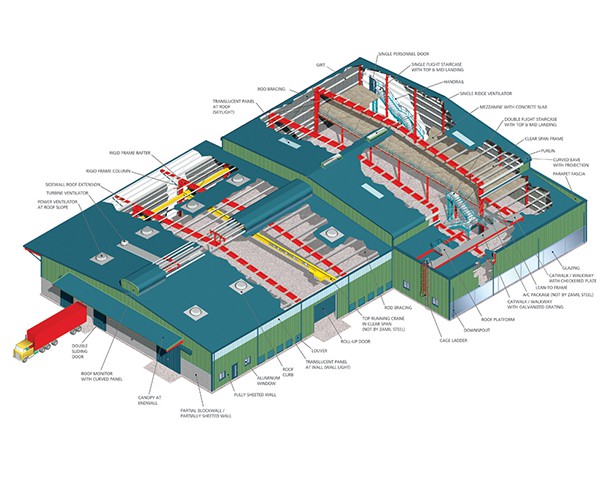

Pre-Engineered Steel Buildings (PEB) are steel buildings “tailor-made” based on the architecture and engineering requirements of the users.

Typically, a Pre-Engineered Steel Building or PEB building is made of three distinctive parts:

- Primary framing members (columns and rafters), which are tapered built-up sections, with large depths in areas of higher stress according to the Bending Moment Diagram

- Secondary structural members (roof purlins, eave struts, wall girts and others), which are light weight cold-formed “Z” and “C” shaped members

- Roll formed profiled sheeting (roof and wall panels)

All the primary framing members and secondary structural members are pre-sheared, pre-punched, pre-drilled, pre-welded and pre-formed in the factory before being shipped to the job site for erection.

The pre-fabricated components are then fixed and jointed via nut & bolt connections at job site.

Benefits

Cost-effective

Saving material on low stress areas of the primary framing members makes Pre-Engineered Steel Buildings more cost-effective than conventional steel building.

Quick Fabrication & Installation

Pre-Engineered Steel Building systems focus on using pre-designed connections and pre-determined material stock to design and fabricate the building structures, thus significantly reducing the time required for design, fabrication and installation.

A versatile building system that fits various applications

Pre-Engineered Steel Buildings can be fitted with different structural accessories including mezzanine floors, crane runway beams, roof platform, catwalk and aesthetic features such as canopies, fascias, interior partitions etc.

The buildings are made fully water proof when applying our MaxSEAM standing seam roofing system with its roof drainage components and trims, making it a versatile building system ; can be furnished internally to serve all functions, and accessorized externally to achieve unique and aesthetically pleasing architecture designs, making it ideal for applications such as factories, warehouses, workshops, showrooms, hypermarkets, etc.