VNSteel Thang Long Coated Sheets Joint Stock Company is a member of Viet Nam Steel Corporation (VNSTEEL) – The largest Steel Manufacturing and Trading State-Owned Enterprise in Viet Nam.

The main products of the company are galvanized sheets and prepainted sheets. They are produced by the German and Italian modernest technology line with the capacity of 100,000 MT galvanized product and 50,000 MT prepainted galvanized product per year. The products are in compliance with JIS G3302, G3312 (Japanese Standards), En10142, EN10169 (European Standards); ASTM A653/A653-08; ASTM A755/755M-03 (American Standards).

Our company’s guidelines are customer orientation with flexible sales policy, perfect service, and thorough after-sales services. VNSteel Thang Long’s coated sheets are standardized to meet the highest demand of product’s quality specifications.

We always try our best to serve customer with deep gratitude by the slogan: “Customer is the first priority”. To partners, we always commit to satisfy all needs in the fastest way so as to develop together. With staff, we always recognize and honor each individual’s effort and contribution to the company’s success.

VNSteel Thang Long’s purpose is to develop the country, enhance the economy and meet the urgent demand of high-grade coated sheets market, which is now a strong point of our company.

Our orientation is to become the leading coated sheets manufacturer in Viet Nam. Therefore, our achievement and development methods have proved the VNSteel Thang Long is going in the right direction to grow.

The core values of VNSteel Thang Long: Trust – Sustainability – Success.

Trusty partner – Highly sustainable products – Successful cooperation

Once again, we, VNSteel Thang Long Coated Sheets Joint Stock Company, would like to thank all of you for your care of our products sincerely and we really hope to become your trusty partner.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Link with

Province/City

Ha Noi Capital

Industrial Park

Quang Minh I Industrial Park

Location Map & Landmarks

NAICS/SIC/VN Code

331513

331512

331511

331221

331210

331110

3399

3325

3324

3322

3321

3317

3316

3313

3312

24100

Certificate

Products of the company

This specification is to control the qualities of color coated sheets in flat, corrugated sheets and coils of Vnsteel Thang Long. This standard based on Japanese Industrial Standard JIS G3302, European Standard EN10169 and American ASTM A755/A755-03.

1. Scope

This specification is to control the qualities of color coated sheets in flat, corrugated sheets and coils of Vnsteel Thang Long. This standard based on Japanese Industrial Standard JIS G3302, European Standard EN10169 and American ASTM A755/A755-

2. Product’s quality specifications

2.1. Bending test

This test is to test the adhesion of paint dry film at 180o . It is also to test the paint dry film strength of products corrugated. There shall not be any flaking of the coating, cracking (visible to the naked eye) or fracture of the base metal on the outside of the bend portion. Specification is 0T-3T.

2.2. Solvent resistance (MEK)

This test is to test the vulcanization of the paint dry film on the galvanized substrate by MEK (Metyl Etyl Keton) testing method. Standard for Solvent resistance is > 100 (DR) without causing the paint dry film take off.

2.3. Pencil hardness test

This test is to test the hardness of the paint dry film by using types of pencils from 2H to 5H. Standard for pencil hardness is ≥ 3H with the paint dry film not scratched

2.4. Impact test

This test is to test the impact resistance of the paint dry film during roll forming. The test is passed when the weight dropped from a heights of 500mm above the test piece without causing paint fry film take off

2.5. Adhesion (Erichsen)

This test is to test the adhesion of the paint dry film (between primer and finish paint with the galvanized substrate) by using Erichsen equipment. The test surface is scored 100 squares of 1 mm by a safety razor blade and then is pressed with the ball head of the tester slowly. The test is passed if 98-100% of the contact surface without paint take off

2.6. Color difference (DE)

This test is to test the color difference between testing piece and standard panel. The color difference < 1% compared with standard panel

2.7. Gloss (picogloss)

This test is to test the gloss of the paint dry film by Picogloss. The gloss ± 3 compared with the standard panel.

2.8 Thickness of the zinc coating- Chromate – Paint dry film

Remark: Further, other values may be applied upon agreement between the purchaser and manufacturer

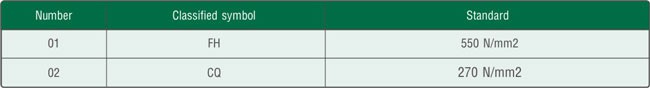

2.9 Tensile strengt

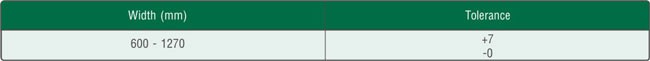

2.10 Tolerance on width

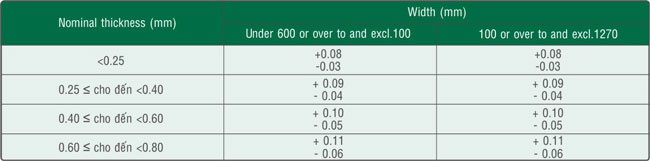

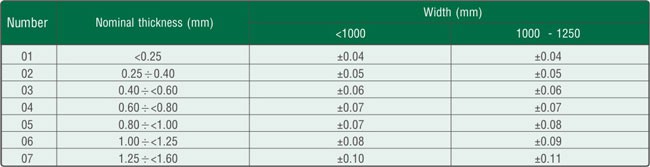

2.11. Tolerance on thickness

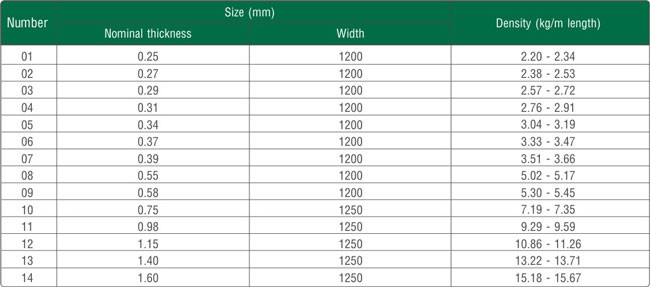

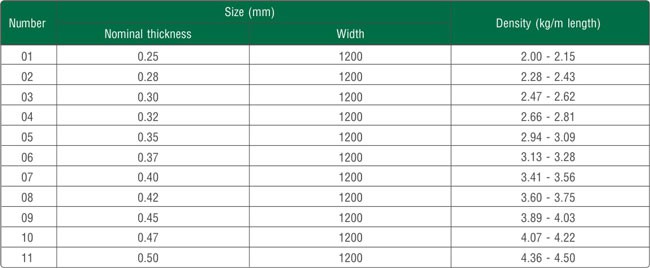

2.12 Density of normal sizes

Remark: The density above, only for reference, the factory shall inform in detail the density of coil to the purchaser.

This specification for hot-dip zinc-coated steel sheets in flat, corrugated sheets and coils is applied for testing the qualities of hot-dip zinc-coated steel sheets in flat, corrugated sheets and coils of Vnsteel Thang Long. This standard based on Japanese Industrial Standard JIS G3302, European Standard EN10142 and American ASTM A653/A653-08.

2. Product’s quality specifications

2.1. Bend test

This test is to test the adhesion of zinc coating at 1800, there shall not be any flaking of the coating, cracking (visible to the naked eye) or fracture of the base metal on the outside of the bend portion. Standard for bending test is 0T-2T.

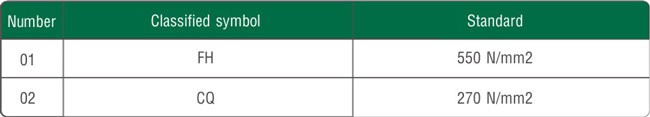

2.2. Tensile strength

Remark: The standard applied for corrugated sheets. Other standards shall be agreed between the purchaser and manufacturer.

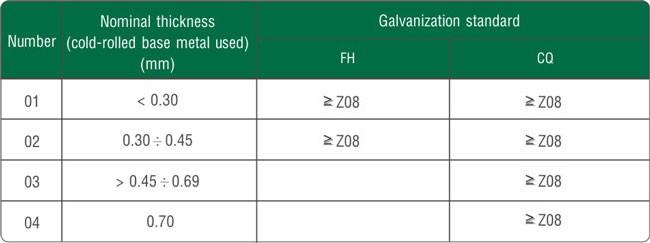

2.3. Coating mass

Table 1: Coating mass standard according to base metal thickness

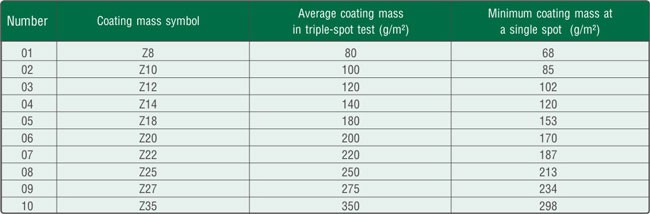

Table 2: Coating mass for equally coated sheet and coil

Remark: Further, symbol and values in parentheses may be applied upon agreement between purchaser and manufacturer.

2.4. Tolerance on thickness

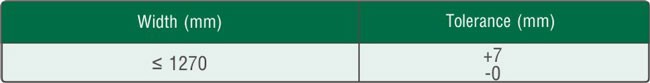

2.5 Tolerance on width

2.6. Density of normal sizes